Until a couple of semesters ago, I taught two classes. One was

a three-hour lecture (Materials and Manufacturing Processes: MEEN 3100), and

the other was a three-hour lab (CAM/Machining and Quality Control: MEEN 3521) in the Mechanical and Manufacturing

Engineering Department. However, I chose

to cut this workload down to the lab only since my vocal cords have been significantly

effected (for the past few years) by allergy, particularly during the spring. While there is more prep time involved working

on the design of lab projects (CAD/CNC Programming, etc.) there is less time spent

lecturing/talking for long stretches at each class meeting. And, quite frankly, students seemed to be

much more attuned to being in the lab, involved with hands-on activities rather

than listening to blah, blah, blah about the physical properties and processes of

materials (Metals, Ceramics, Polymers, Composite Materials, etc.)!

In particular it is hard to fathom in a classroom

environment the underlying principles of group technology and the flexible

manufacturing systems prevalent in today’s ever so competitive global manufacturing. Thus there is no substitute for whatever

degree we can engage our students in hands-on manufacturing/machining process

planning, part-programming, actual CNC

operating system settings (Fadal Machining Center, HAAS Turning and Machining MCU, CMC, etc.),

and allow them to above all actually ‘make some chips’, i.e. do actual

machining/engraving and alike. I for

one, most certainly, provide them with opportunities to apply the theoretical

principles that have been drilled in the classrooms with hands-on application in

the labs.

In case that you may not be familiar with TSU, here are some

selective excerpts from the TSU website as well as a link for your perusal to

our ME program. http://www.tnstate.edu/engineering/

LOCATION

Nashville, Tennessee: state capital and second-largest

city in the state, population 600,000; known as “Music City USA” and “The

Athens of the South”; center of government, banking, insurance, publishing,

healthcare, transportation, art, culture, and education; beautiful main campus

sits on 500 acres near the Cumberland River in a residential neighborhood just

10 minutes northwest of downtown

ACADEMIC PROGRAMS

77 majors in eight undergraduate and graduate colleges

and schools; arts and sciences; business; education; engineering, technology,

and computer science; health sciences; public service and urban affairs;

agriculture and consumer sciences; nursing

DEGREES

Undergraduate: Bachelor of Arts; Bachelor of Science;

Bachelor of Business Administration; Bachelor of Interdisciplinary Studies;

Bachelor of Professional Studies; Bachelor of Science in Nursing; Associate in

Applied Science; Teacher Certification

Graduate: Master of Arts; Master of Science; Master of

Business Administration; Master of Criminal Justice; Master of Education;

Master of Engineering; Master of Public Administration; Master of Science in

Nursing; Certificate in Health Administration and Planning; Certificate in

Nonprofit Management; Specialist in Education

Fall 2011 semester enrollment: 7,105 undergraduate and 2,060 graduate

students

450 full-time academic faculty; 72.7% of faculty have

terminal degrees; undergraduate student-faculty ratio: 16 to 1

Tennessee State University is accredited by the

Commission on Colleges of the Southern Association of Colleges and Schools;

-----------

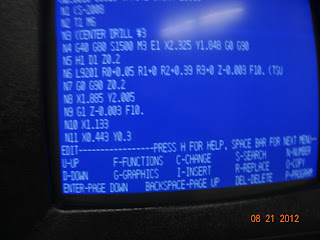

Here are some selective shots from our Mech. and Mfg. Engineering (3 out of 5) labs:

Hass MCU: Machining & Turning Centers

Program Library

Engraving program...

Conventional Machining Lab

(One of two labs)

Newly installed Plastic Injection Molding Press (to be fully operational Jan./2013)

Senior class/lab activity...

Faculty Directory (partial list)...

*

*

No comments:

Post a Comment